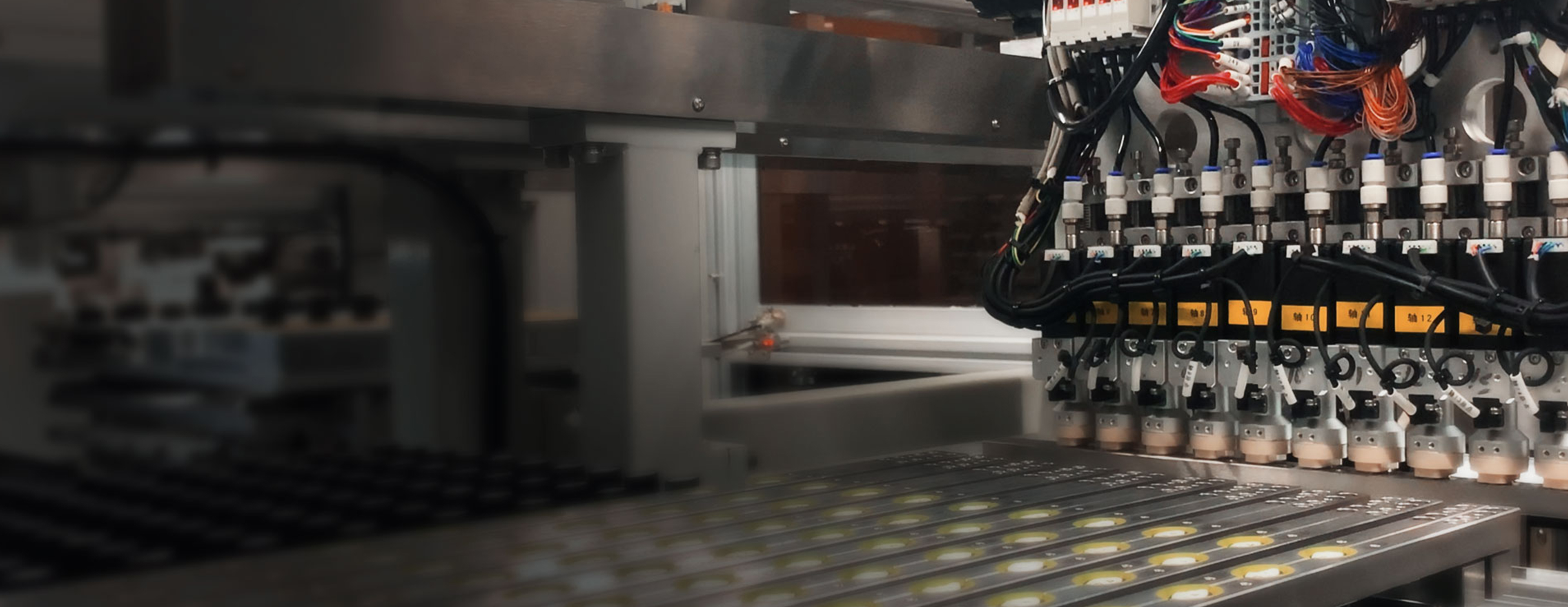

Introducing automated production systems

In previous decades, implementing new tasks in traditional manufacturing production chains could involve hours or even days of user training. By contrast, reprogramming a robot or machine as part of an automated system is a simple, speedy process. In automated systems, sensors, controls, and actuators are integrated to perform a function with minimal or no human intervention. With the development of cutting-edge techniques, innovative automated systems make a significant contribution to production ability. Let's take a look at ALD's adoption of this technology.

Three key features and benefits of ALD's automated production lines

1. Digitization system

ALD's intelligent manufacturing processes use the MES Pro system, which tracks and documents the transformation of raw materials to finished goods. It provides information that helps manufacturing decision-makers understand how current conditions can be optimized to improve production output. This automated operating system ensures the accurate control of multiple elements of the production process, such as process control, production scheduling, visual boards, information tracing, and abnormality monitoring. Consequently, continuous mass production is possible 24/7, with improved productivity, greater accuracy, and reduced assembly times. Production capacity is enhanced, with ALD able to generate 50 million pieces of daily output.

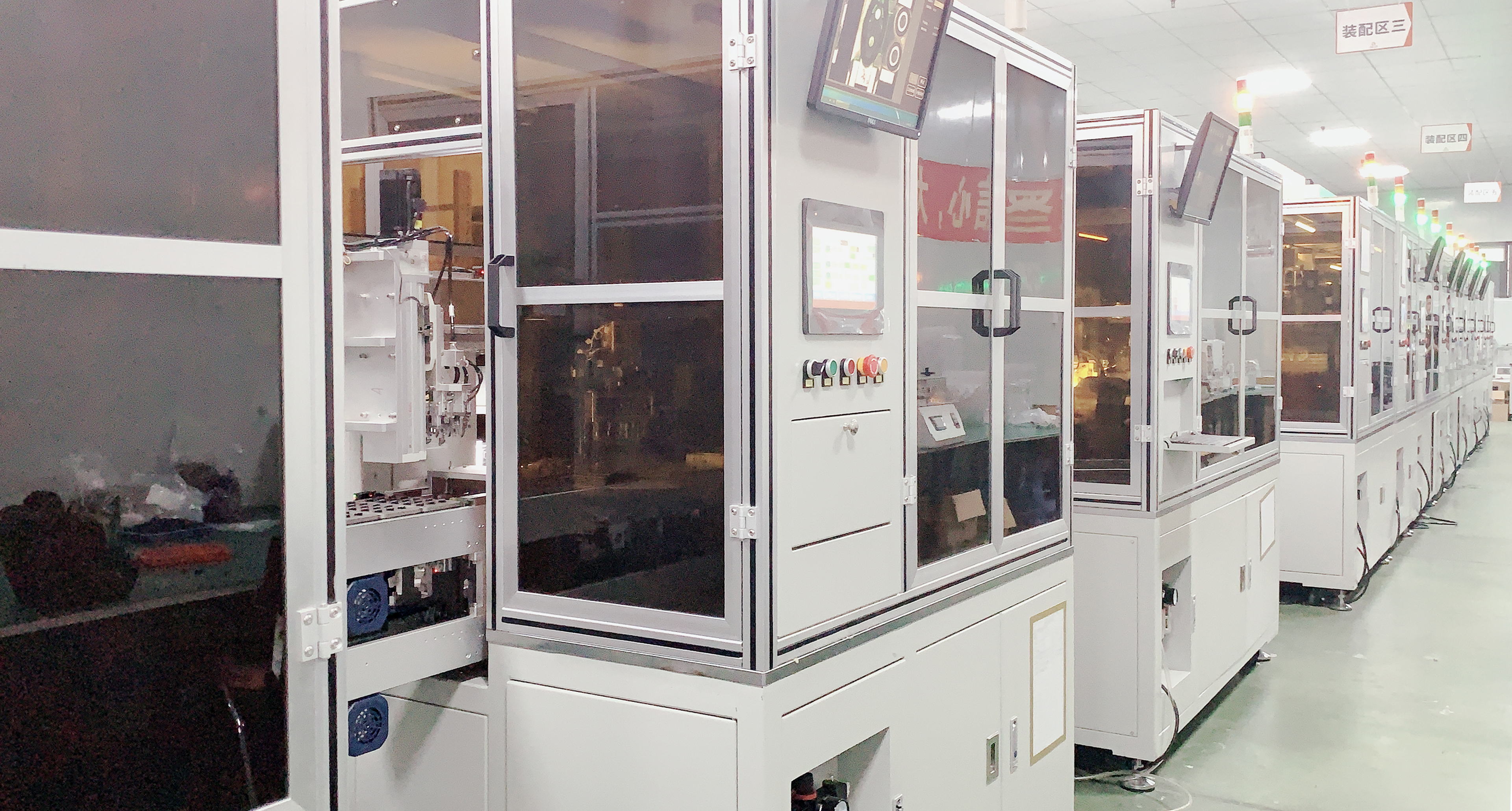

2. Quality assurance

ALD has a large and diverse range of automated production equipment, 180,000 ㎡workshop areas, and 3,500 staff. Automatic production processes include loading tests, material processing, product assembly, atomized liquid injection, and performance testing. As a result, ALD can efficiently ensure product quality and uniformity, alongside a materials-loss reduction in the whole production process. In this way, ALD's intelligent manufacturing offers clients the best quality products with minimal waste.

3. Flexible production model

Besides efficient, automated mass production, ALD is committed to maintaining a flexible production model. Specifically, flexible manufacturing is a system that allows a certain level of adaptability, making it easy to react to predictable or unpredictable changes. This system enables the industry to respond to customer orders quickly by introducing products effortlessly and providing a broad product range. Flexible production provides machine flexibility, increasing the resilience in processes as the manufacturing system absorbs large-scale changes such as production assortment size, capacity, and productivity. As a result, ALD can respond to clients' issues quickly, including short-time adjustments and individual requirements, to meet the satisfaction of product diversity in the future.

Although the initial investment in industrial automated systems might seem relatively high, implementing these operating systems will reduce data analytics costs. In turn, this automated data analysis minimizes the risk of machine failure and service interruptions, helping keep production flowing smoothly. In conclusion, automated production technology has played an essential role in the development of ALD's intelligent manufacturing strategy. Employing such technology demonstrates to clients ALD's competitive strength and sophistication as a vaping hardware solution supplier that can offer the best service.