Following many years’ e-cig industry evolution, ceramic and cotton are two of the market’s mainstream coil options. Both have pros and cons when installed into an atomizer, and today we will look at ALD’s efforts to diminish the shortcomings of cotton coil technology through cutting-edge research and development. Following processes including thousands of experiments, we developed a groundbreaking cotton coil technology that combines the advantages of both ceramic and cotton.

The Disadvantages of Traditional Cotton Coils

The biggest drawback of the ordinary cotton coil is its relatively unstable material structure compared to ceramic. One effect of this is that the production process for cotton coil atomizers requires extensive manual work, which precludes large-scale automated production, resulting in low product consistency as well as limited production capacity. In addition, cotton coils relatively quickly lead to dry burning or the spilling of e-juice due to their low structural strength. These two key shortcomings make many leading manufacturers pick ceramics as the primary material for atomizer coils.

What Sets ALD’s Cotton Coil Technology Apart?

1. High Flavor Reproduction and Consistency

Compared with the market’s ordinary cotton coils, the ALD cotton coil increases the consistency of taste by 30%. To achieve this feat, ALD selected cotton with a high Micronaire factor as the material for the atomizer coil. Micronaire is a measure of the air permeability of cotton fibers and is an indicator of the fibers’ fineness and maturity; when applied in atomizers, a higher Micronaire factor enables better oil conductivity and toughness. In addition to good oil conductivity, this cotton material provides excellent liquid storage capacity and temperature resistance, giving more edge to the aerosol’s flavor reproduction. The aerosol produced is fuller and more satisfying, and the material avoids the common problems of dry burning and burned taste associated with the material in ordinary cotton coils. In short, ALD’s cotton coils ensure a stable release and lasting flavor, delivering a consistent vaping experience with every puff.

2. High Quality, Low Production Cost

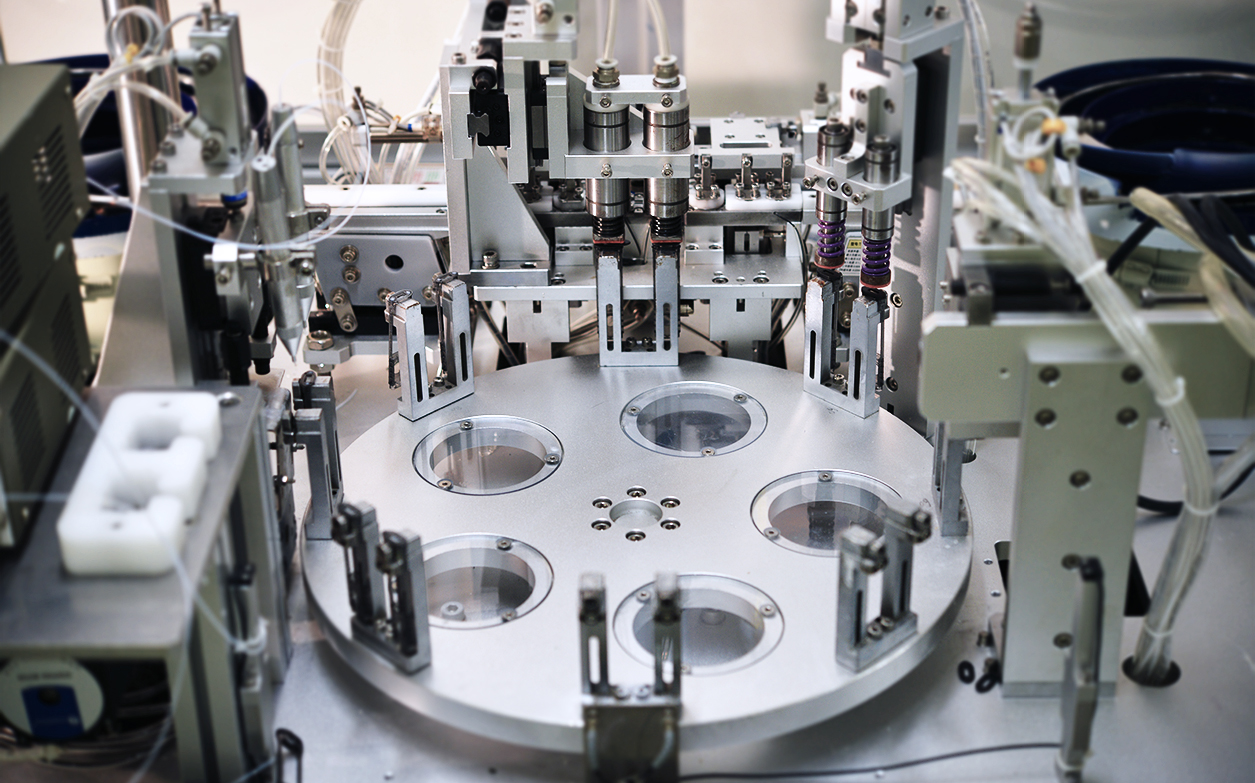

Compared with ceramic coils’ rigid and stable structure, cotton features a soft and unstable construction. Hence, it is not easy to put into automated production. However, ALD addresses this issue through a unique flat stacking and embedment approach, which eliminates the need for manual intervention. In addition, ALD has introduced a modular structural design similar to ceramic coils, facilitating automated production and eliminating assembly errors. These design innovations allow for high, consistent product quality and low production costs. ALD’S intelligent manufacturing systems enable considerable monthly mass-produced output and a 99.7% production yield rate.

3. High Safety

ALD is committed to ensuring aerosol safety in cotton coil atomizers. Several performance testing centers have been set up to manage the strict control of processes, including incoming material inspection, production-line inspection, and final product testing, for high aerosol safety assurance. In addition, every prefilled cartridge undergoes a strict atomization test to ensure aerosol is safe for all users in each product.

ALD offers a comprehensive integration system for cotton coil technological solutions. These solutions combine the advantages of ceramic and cotton coils with the innovative introduction of a new modular structure design. In this way, the aerosol from the atomizer maintains the best flavor associated with traditional cotton coils while enjoying the benefits of stability and quality thanks to the automated production processes. As a leading vaping manufacturer, we are committed to constantly exploring more high-end and innovative technologies to provide outstanding products for our clients and customers.